“We develop individual cooling solutions. First, we need to know our client’s specific cooling application and understand the process. In the next step, we develop a cooling solution based on existing modules that perfectly suits the requirements.”

Rolf Sebastian,

Global Product Management

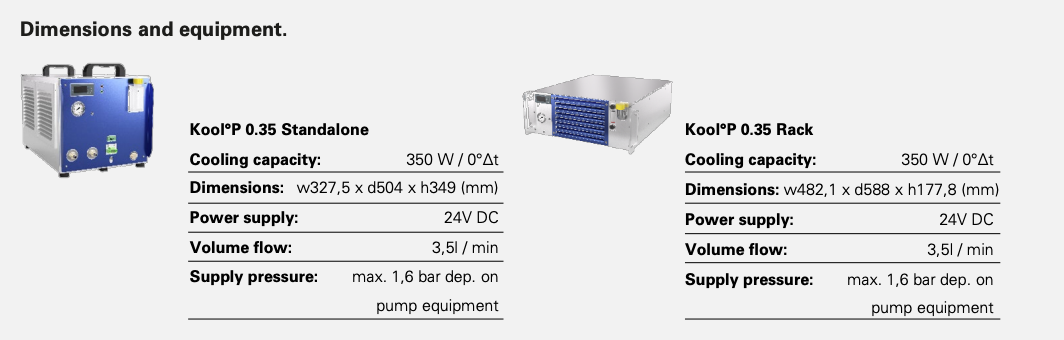

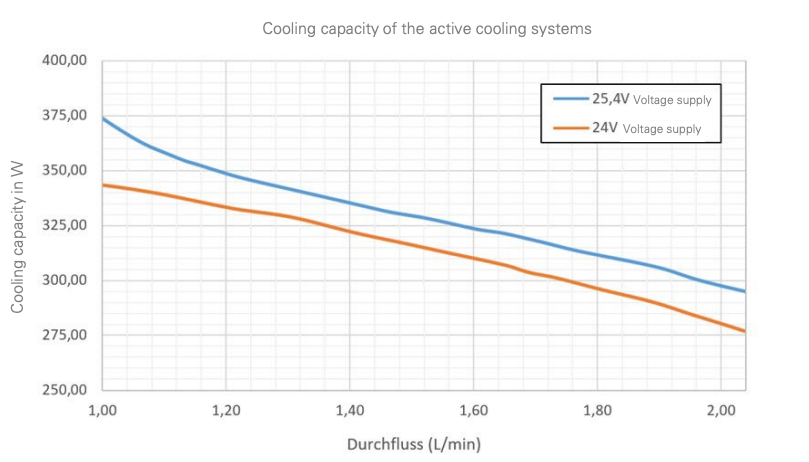

Cooling capacities up to 350 W.

Kool°P series.

- For complex laser systems in the small power range.

- For medical and laboratory analysis technology.

- Refrigerant-free cooling solutions.

- Low-maintenance and low-vibration cooling systems.

- Standard cooling capacity of 350 W.

- Booster variant is a net cooling capacity of up to 600 W with a temperature stroke of 0 Kelvin.

The well-equipped Peltier coolers offer high temperature stability with particularly quiet operation and are optionally available as a plug-in solution for a 19″ rack or classically as a stand-alone solution.

- Low-maintenance and low-vibration cooling system. Vibration-free through the use of Peltier technology.

- More cooling capacity. In addition to a standard cooling capacity of 350 W, the booster variant enables a net cooling capacity of up to 600 W with a temperature stroke of 0 Kelvin.

- Well-equipped. Excellent sensor technology and controllability.

- Reliable. High temperature stability combined with quiet operation.

- Variant. Optionally available as 19″ rack or stand-alone solution.

Cooling capacities 2 kW to 70 kW.

WKS series.

- From the plug-in universal solution to the standardised product.

- Wide range of customization options.

- Suitable for a wide range of process cooling requirements.

- Most common areas of application: laser and machine tools, plastics and packaging industry, as well as processes in the print or food & beverage sector.

- Easier maintenance thanks to variably applicable air intake plates (left or right for maximum flexibility).

Customizable. From the ready-to-plug-in universal solution to the standardised product with extensive equipment options.

Flexible installation options. The variable air intake plates on the right or left side ensure flexible positioning of the units in the room.

Intelligent. A service technician can also check the products during operation. No breakdowns or unnecessary downtimes.

Reliable. All models comply with the currently valid EC directives, standards and regulations: ISO 9001, EN 378, VDE and BGV.

Logistics. Thanks to the refrigerant charge < 12 kg and non-flammable refrigerant, the units can be transported by air freight without any problems.

Worldwide use. The units can be supplied bifrequency (400 V / 3 Ph / 50 Hz and 460 V / 3 Ph / 60 Hz).

Exemplary equiment options…

- Outdoor installation

- Continuously variable speed control for fans

- Dirt filter

- Shut-off devices (non-return or solenoid valves)

- Tank heating for temperature control

- Stainless steel water circuit, or PVC for deionised water

- Water-cooled design

- Pump pressure freely selectable

- Control accuracy +/- 1 K or 0.5 K

- Pass-through system

- Liquefier protection screen, air filter mat*

- Air filter mat monitoring

- Reduced noise design

- Overflow valve*

- Fixed bypass

* Standard -> already integrated in the cooler

… in the overview.

- Flow monitors

- Automatic water refill

- Pump switch-off

- Flow rate monitoring

- Guide value monitoring

- Two-circuit system

- 24 V / DC control*

- Special voltages and frequencies

- Digital thermometer

- Limit value monitoring*

- Differential temperature regulation

- Tropical version

- Bus connection

- Individual fault display

- Special colour according to RAL

Cooling capacities 50 kW to 230 kW.

PC series.

- Professional liquid coolers – suitable for all applications.

- Extremely high reliability.

- Cooling capacities up to 230 kW.

- Various additional functions and options.

In addition, an energy-saving system can be used (ESS system), which can achieve additional energy and cost savings at low ambient temperatures.

- Solid. Safe operation is guaranteed by the right selection and the use of components from renowned manufacturers.

- Reliable. All models comply with the currently valid EC directives, standards and regulations: ISO 9001, EN 378, VDE and BGV.

- Energy-saving. The optional energy-saving system (ESS module) provides additional energy and cost savings at low ambient temperatures.

- Durable. Riedel Kooling service does not end with the delivery and commissioning of your system. Through adapted maintenance, your system will continue to perform its task reliably and trouble-free for years to come.

Exemplary equiment options…

- Outdoor installation.

- Continuously variable speed control for fans (Standard: PC502 – PC1602)

- Dirt filter.

- Isolation valves (check valves / solenoid valves).

- Tank heating for temperature control.

- Stainless steel water circuit, or PVC for deionised water.

- Water-cooled design.

- Liquefier protection screen, air filter mat.

- Air filter mat monitoring.

- Reduced noise design.

- Overflow valve.

- Fixed bypass.

… in the overview.

- Flow monitors.

- Automatic water refill.

- Pump switch-off.

- Flow rate monitoring.

- Guide value monitoring.

- Two-circuit system.

- Special voltages and frequencies.

- Digital thermometer.

- Limit value monitoring.

- Differential temperature regulation.

- Control cabinet fan.

- Bus connection.

- Individual fault display.

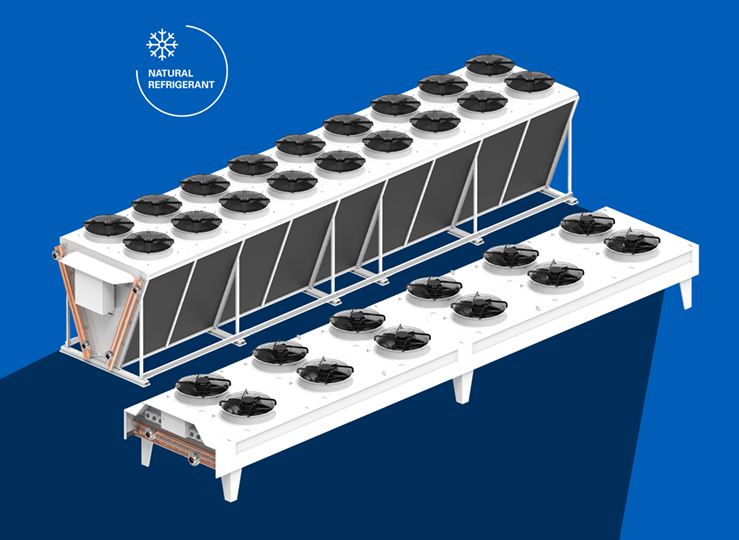

Cooling capacities 300 kW to 1,000 kW.

Kool°T series.

- Air-cooled chillers for indoor/outdoor installation.

- Cooling capacities between 300 kW and 1,000 kW.

- Especially for applications with high cooling requirements.

- Particularly high reliability with the lowest possible energy consumption at the same time.

Various configuration options combined with the particularly large selection of equipment options make these chillers a true all-round talent.

- Intelligent. Already during the development process, the arrangement of the individual components was designed in such a way that easy accessibility of the components in case of service is guaranteed, e.g. during maintenance.

- Compact. The unit dimensions have been optimised so that even with a high cooling capacity, little space is required for installation.

- Versatile. Various configuration options combined with a wide range of equipment options make these coolers an all-round talent.

- Efficient. Thanks to the modular design of the cooling circuit with up to 6 compressors, the cooler is efficient and quiet even in partial-load operation.

- Innovative. Modern components from renowned manufacturers, e.g. electronic expansion valve, EC fans, microchannel condenser.

Exemplary equipment options:

- Min. / max. phase monitoring.

- Coated condenser (e-coating).

- Hydraulic module.

- Vibrating metal feet.

Dry coolers and hydro cooling systems.

Kool°F series

- Available in a wide range of capacities.

- Customized solutions enable optimal integration into the respective system concepts – the individual conditions at the installation site can be fully taken into account.

Construction types. Open and closed cooling towers, wet and dry coolers, condensers for various refrigerants.

Cooling media. Water, glycol mixtures, deionized water, various refrigerants or oil can be used.

High performance. Even in limited space.

Quiet operation. Depending on the installation site, whether residential or industrial, our systems comply with the required sound limit specifications.

Connectivity. A wide range of communication interfaces for reading out and controlling operating parameters.

Heat pump solutions up to 2,000 kW.

Kool°H series.

- Customized heat pumps for a wide range of industrial applications and temperature ranges.

- For cooling, heating, waste heat recovery and hot water production.

- Large performance range. We offer a large product portfolio of air-to-water heat pumps from 50 kW.

- Temperature range. A wide range of heat pump solutions available to provide hot water up to 120 °C.

- Refrigerants. Use of a wide range of refrigerants matched to your application, also available with natural refrigerant.

- Targeted waste heat utilization. Surplus heat from the heat sources air, water or brine, which is produced as a waste product during production processes, for example, is raised to a higher usable temperature level by a heat pump and efficiently fed back into the energy process.

- Energy efficiency. CO2 emissions, operating costs and maintenance costs are sustainably reduced.

- Planning of the overall energy concept. Concept development and coordination of all trades.

- Advice and support. During the implementation and installation of the system.

- Eligible for subsidies. Please contact us personally regarding the subsidy level of our products.

Slide-in, stand-alone & system cooling solutions.

- Designed for reliable cooling.

- Standard or as a plant-specific system solution.

- Even in extreme climatic conditions, such as in South-East Asia.

- Suitable for worldwide use.

- Perfect for highly sensitive laser systems – from CO2 lasers to solid-state lasers and disk lasers to diode lasers.

- In focus: integrated cooling modules as a smart plug-in element. Cools precisely and can be easily integrated.

- Active or passive cooling unit designed as a slide-in cooler.